"Support" Your 3D Prints: 45° Rule and YHT Rule for Optimal Supports

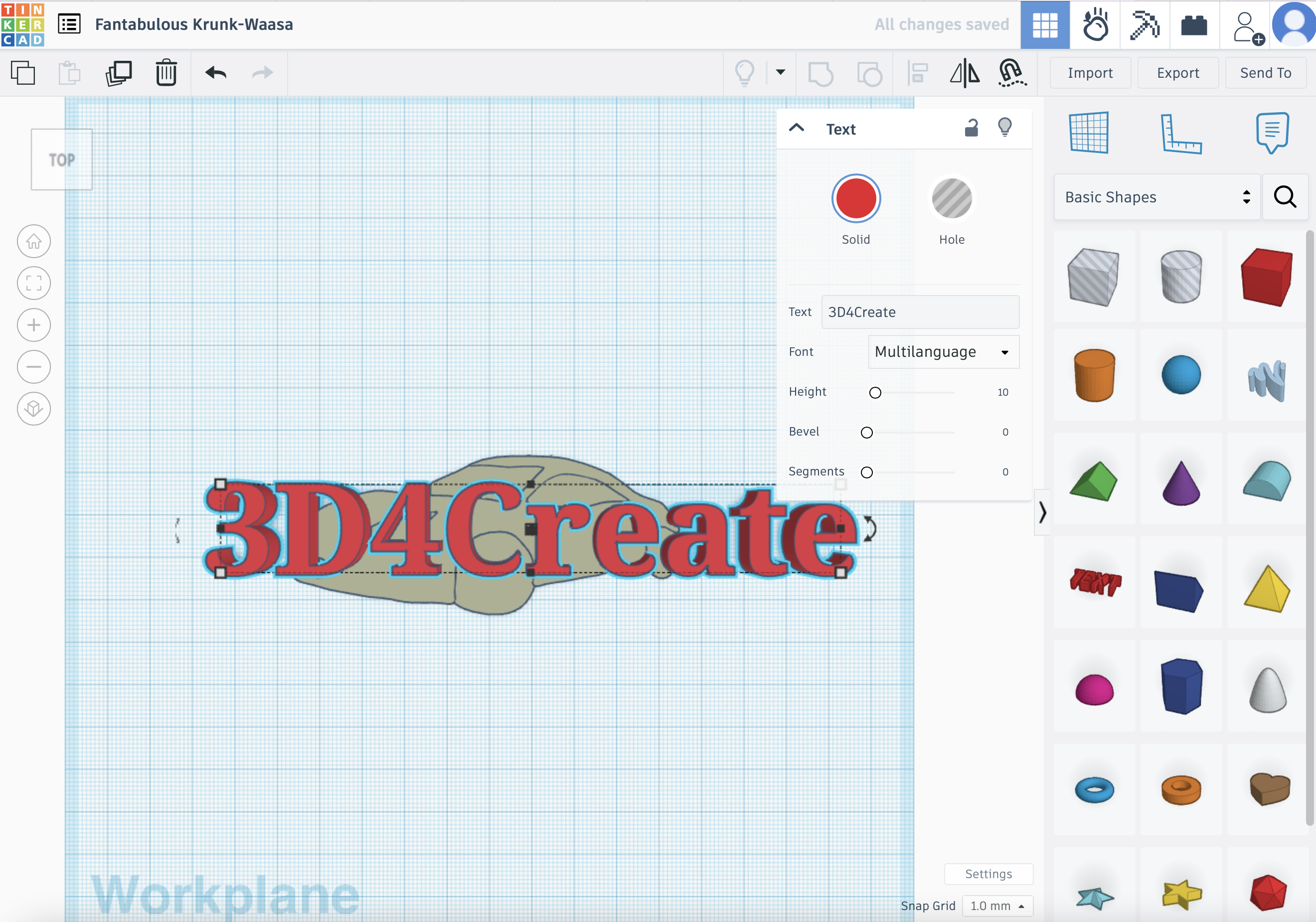

Sep 29,2023 | 3D4Create

Supports act as little pillars or scaffolds to hold up overhanging parts of a 3D model while printing.

Understanding key support rules like the 45° rule and YHT rule will enable you to add optimal supports where needed. This prevents wasted filament and time from failed prints.

I. Why Supports Are Crucial for 3D Printing Success

Due to the way 3D printers build objects layer-by-layer, they cannot print protruding structures in midair. Gravity causes overhangs and angles past a certain degree to collapse or sag without an underlying base.

Supports provide this essential base, bridging the gap between the print bed/completed layers and the overhanging section as it prints.

Well-placed supports hold up overhangs during printing and are later removed once the print is complete. Without them, steep angles will end up drooping, warping, or sticking to the nozzle as they print, leading to spaghetti-like failed prints.

Lastly, supports allow you to get creative and print models with shapes you couldn’t otherwise manufacture. Options like topological optimization in CAD produce super organic shapes with intense overhangs that supports make manufacturable.

Supports are very important for 3D printing

II. Overview of Support Types and Placement

1. Rafts vs Regular Supports

There are two main types of print supports:

- Rafts: Full layers of dense material under the entire print acting as a base layer. Good for models with small contact points.

- Regular supports: Sparse scaffold-like structures only placed where needed. Conserve material and are easier to remove.

Rafts provide a flat, stable surface to print on and prevent warping. But they use a lot more material and are harder to detach after printing.

Regular supports with optimized settings are usually the better option. They act as pillars holding up specific overhangs and are easily clipped off after the print finishes.

2. Where Supports Are Needed

Supports are necessary anywhere the angle of an overhang passes around 45 degrees or more. This includes:

- Steep vertical walls

- Angled/curved ceilings

- Bridging gaps

- Internal cavities

- Floating objects not connected to the rest of the print

Generally supports should touch the bed to prevent the model from getting knocked loose during printing. For floating pieces, an anchor support connects them to the bed.

III. The 45° Rule for Angled Overhangs

1. What the 45° Rule Means

The 45° rule is a guideline for the maximum angle you can print before needing supports.

At 45° exactly, the overhang perimeter will print decently but may have poor-quality top layers. Anything beyond 45° will start drooping without supports.

This rule assumes you are printing with standard filaments like PLA, PETG, or ABS. More exotic filaments like flexible TPU can bridge larger overhangs without supports.

Supports are needed for structures that beyond 45°

2. When to Use the 45° Rule for Overhangs

To quickly decide where supports are needed, visually divide your model into square blocks. For any surface or edge steeper than 45°, plan to add supports.

Some CAD programs like Blender even have tools to color code surfaces by angle as an easy visual guide. Green is safe, yellow is borderline, and red needs supports.

Don't rely solely on this 45° rule though, as actual overhang ability depends on factors like print speed, material, nozzle size, part cooling, and overhang length. But it provides a good starting point.

Supports are also not needed for vertical walls, as they print perfectly straight with no angle. Preslice the model to see all problematic areas needing supports.

IV. Understanding the "YHT" Rule

The YHT principle helps explain the need for support structures in additive manufacturing with 3D printed models.

Y: The arms of the letter Y extend at a 45° angle, without requiring support structures. Overhang angles greater than 45° may need support.

H: If the distance between the vertical elements of the letter H is less than or equal to 5mm, the horizontal element can be 3D printed without support using bridging. Distances greater than 5mm may require support.

T: The arms of the letter T extend at a 90° angle, requiring support structures.

V. Optimizing Your Support Settings

To conserve material and improve ease of removal, optimize your support settings.

1. Support Patterns and Density

- Use linear or zig-zag patterns to reduce material use and prevent suction when removing supports.

- Drop density to around 20-30% for easier removal. This creates a sparse scaffold-like structure.

- Add a few interface layers at >95% density where supports touch the model for better bonding.

2. Easy Removal Settings

- Set a small horizontal expansion gap between supports and model. This reduces surface roughness and lets supports pop off cleanly.

- Increase the XY Separation Distance so support bases peel away more easily from the model bottom.

- Adjust the support Z Distance to get just enough adhesion for printing without too much for removal.

- Enable Support Roofs and Floors to add a flat, solid base that's easier to start removing supports from.

Improper support settings can ruin your print (photo: 3D Printing Stack Exchange)

VI. Removing Supports and Finishing Tips

Removing supports is an art that takes some finesse. Here are some tips:

1. Cleanly Removing Different Support Types

- Snap off: Support structures should cleanly snap off flush with the model with little force. If properly optimized, this is the ideal.

- Cut/pluck: Use flush cutters to snip where supports meet the model, then pluck out the support stem. Great for tricky overhangs.

- Dissolve/melt: Some filaments like PLA can be slowly melted/dissolved away with solvents or heat. Useful for supports inside complex shapes.

2. Sanding and Finishing for Smooth Results

Any remaining nubs or scuff marks can be gently sanded down with fine grit sandpaper (400+ grit) for a glass-smooth finish. Avoid over-sanding delicate features.

Gaps can often be filled with cyanoacrylate glue, epoxy putty, or plastic filler. Then sand and paint for an invisible repair.

With optimal placement using the 45° and YHT rules, plus properly tuned support settings, you'll achieve easy, seamless support removal for perfect prints every time.

eSUN ABS+ Filament for 3D Printer 1.75mm 1KG

VII. Conclusion

- Supports are required to print overhangs past around 45° and properly bridge gaps.

- Well-placed, optimized supports prevent wasted time and filament from failed prints.

- The 45° rule helps identify overhangs needing support.

- Use the YHT rule to position supports close enough to overhangs for optimal contact.

- Settings like low density and expansion gaps improve support removal.

- Careful support removal and finishing results in smooth, professional looking prints.

Implementing good support habits will take your 3D printing skills to the next level. No more droopy failed prints! Proper supporting opens up new opportunities to print geometries previously unmanufacturable.

FAQS:

1. What is the YHT rule in 3D printing?

The YHT rule in 3D printing helps determine optimal support placement. YHT stands for the horizontal distance between the support and model (Y), the height of the support (H), and the layer thickness (T). The rule states that Y should be less than H divided by 2T. This ensures the supports are close enough to properly contact the overhangs.

2. What is the best support pattern for 3D printing?

The best support pattern for most FDM prints is a linear or zigzag pattern. This uses less material than a solid pattern and makes the supports easier to remove after printing without suction. A density around 20-30% is ideal for a good compromise between print success and material use.

3. What is the 45 degree rule in additive manufacturing?

The 45 degree rule is a guideline that states overhangs steeper than 45 degrees will likely require supports when printing with common materials like PLA and ABS. At 45 degrees exactly, prints may still work but have poor top surface quality without supports. Beyond 45 degrees, drooping and failures become likely.

4. What is the best support X Y distance?

The optimal support X and Y distance depends on factors like the model design and your print settings. But as a general guideline, an X and Y distance of 0.6-1mm between the supports and model provides enough gap for easy removal while still supporting the overhangs.

See Also:

How to minimize supports when 3D printing?

PLA, ABS, Nylon & PETG Shrinkage & Compensation: Essential Facts

Getting the Best Results: Optimal 3D Printing Temperatures for PLA, ABS, PETG, TPU, Nylon