The Ultimate Guide for 3D Printing Supports

Aug 03,2023 | 3D4Create

I. Introduction

3D printing supports are structures generated by the slicer software to provide stabilization, prevent drooping and enable overhangs when 3D printing models. Supports provide a foundation for sections of prints that have nothing underneath while printing layer by layer.

Understanding when to use supports, the different types, and how to properly remove supports allows maximizing print success. This ultimate guide covers everything you need to know about leveraging supports for your 3D printing projects.

II. What are Supports in 3D Printing?

3D printing supports, also called scaffolding, are temporary structures that are printed along with the main model geometries. They are automatically generated by the slicer software. Supports adhere to the print bed and model at defined contact points to provide stability during printing.

Supports prevent deformity, drooping, stringing, and other defects that can result when trying to print overhanging geometries without an underlying base. After printing completes, the supports are detached and removed, leaving only the finished print behind.

III. When are Supports Needed in 3D Printing?

3D printer supports become necessary for models that have the following:

1. Overhangs

Any sections of the print that overhang the layer below at an angle greater than around 45 degrees will require supports to avoid drooping and sagging.

2. Bridges

Where parts of the model have gaps or spans open space, bridging supports help hold up these delicate sections.

3. Complex Geometries

Highly complex shapes with intricate cavities, tunnels, textures, or moving components often benefit from supports to print successfully.

IV. Support Types and Settings

There are a few key types of support structures, each with their own advantages:

1. Touching Build Plate

This is the most common support type, generating supports anchored to the print bed stretching up to the model.

2. Everywhere

Everywhere supports generate supports connecting both to the bed and between sections of the model that overhang.

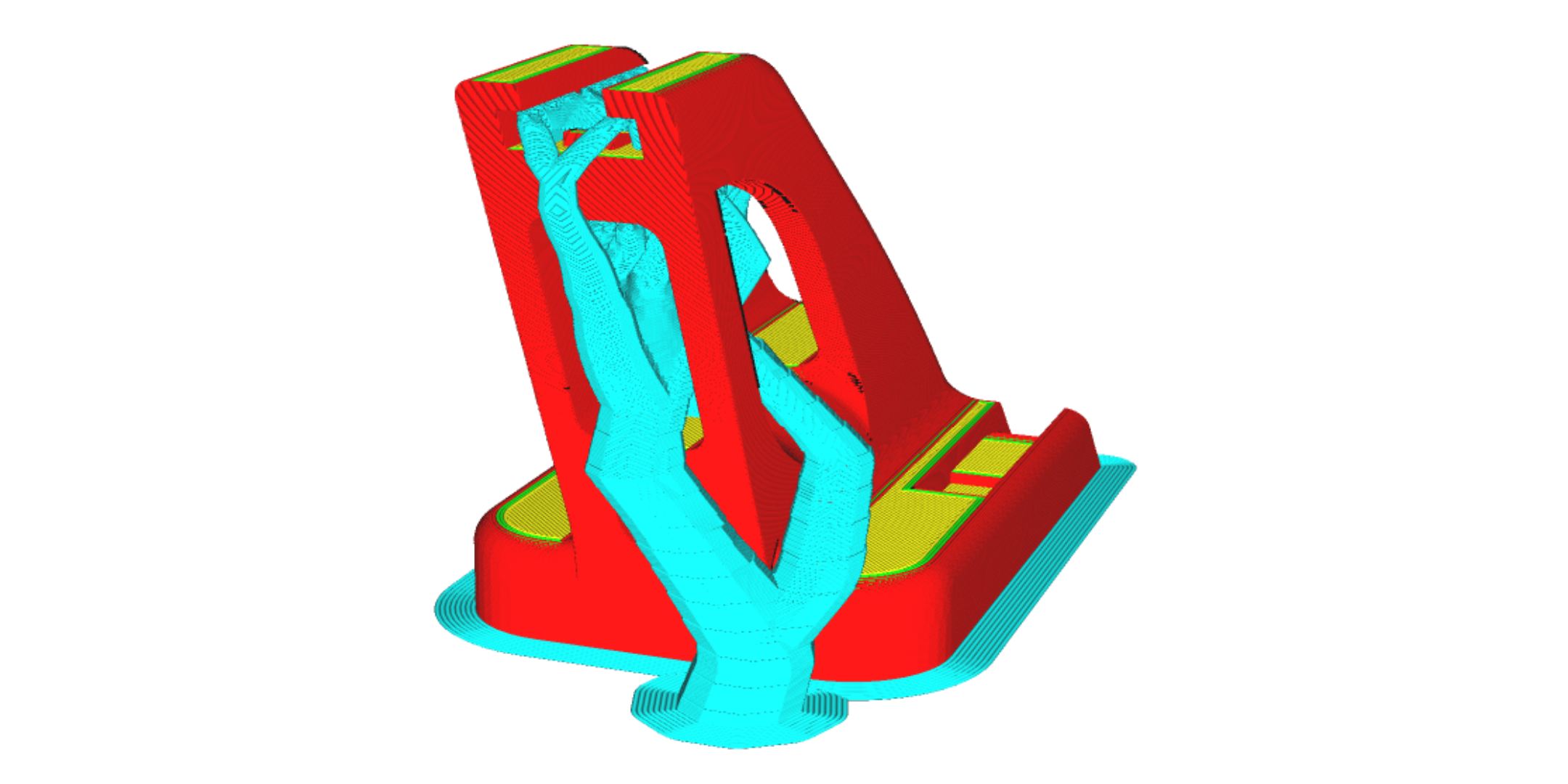

3. Tree Supports

Tree supports use a branched, tree-like pattern that touches the model minimally, saving material and making removal easier. In the slicer, you can fine tune settings like support density, offset from model, interface layers, and more to customize the supports generated.

Example of tree supports (photo: UltiMaker)

V. Optimizing Support Placement for 3D Printing

Proper placement of supports is crucial for efficiency and print quality. Some tips:

1. Orientation

Rotating the model can sometimes eliminate the need for supports altogether or minimize where they are required.

2. Interface Layers

Interface layers create a smoother surface where supports contact the model for easier removal.

3. Density

Lower density supports use less material. But higher density provides better structural rigidity during printing.

Illustratuon to optimize Cura support settings (photo: All3DP)

VI. Support Material Options for 3D Printing

Choosing the right support material for your printer is important:

1. PLA, ABS, PETG

The same material as your printed part, like PLA or ABS, makes removing supports easy by breaking away cleanly. However, PLA and ABS have many differences that you need to pay attention to.

2. Soluble Support Material

Water soluble support material like PVA dissolves away from the printed part effortlessly.

3. Breakaway Supports

Some ABS and ASA filaments offer snap-away support structures that are very easy to remove.

VII. Conclusion

Understanding how to work with 3D printing supports opens up new abilities to successfully print challenging shapes with overhangs and bridging. From configuring support generation settings, to strategic placement, using specialized materials, and proper finishing, mastering support use is a valuable skill for pushing the limits of your 3D printing potential.

FAQS

1. What is the minimum angle that requires supports?

Generally you'll need supports for overhangs greater than 45 degrees. Anything less than 45 degrees may print without drooping. Play it safe and use supports for overhangs greater than 30-40 degrees.

2. Do tree supports use less material than regular supports?

Yes, tree supports use significantly less material compared to standard "touching build plate" supports since they minimize contact points on the model. This saves on filament.

3. How do I remove supports from tiny details without damaging them?

For small details, avoid tearing supports off forcefully. Instead, use flush cutters to trim supports near the model surface. Then gently scrape away any remaining material with a hobby knife and finally sand any remnants smooth. Take it slowly to avoid damaging intricate details.