The Secret to Cheaper Toys? - 3D Printing

Aug 07,2023 | 3D4Create

I. Introduction

With a desktop 3D printer, you can now produce one-off toys as needed rather than relying on mass-produced products. But is taking the DIY approach cost-effective?

In this guide, we’ll look at considerations like printer and filament costs, toy retail pricing, print times, quality differences, and customization to help you decide when printing toys at home makes financial sense.

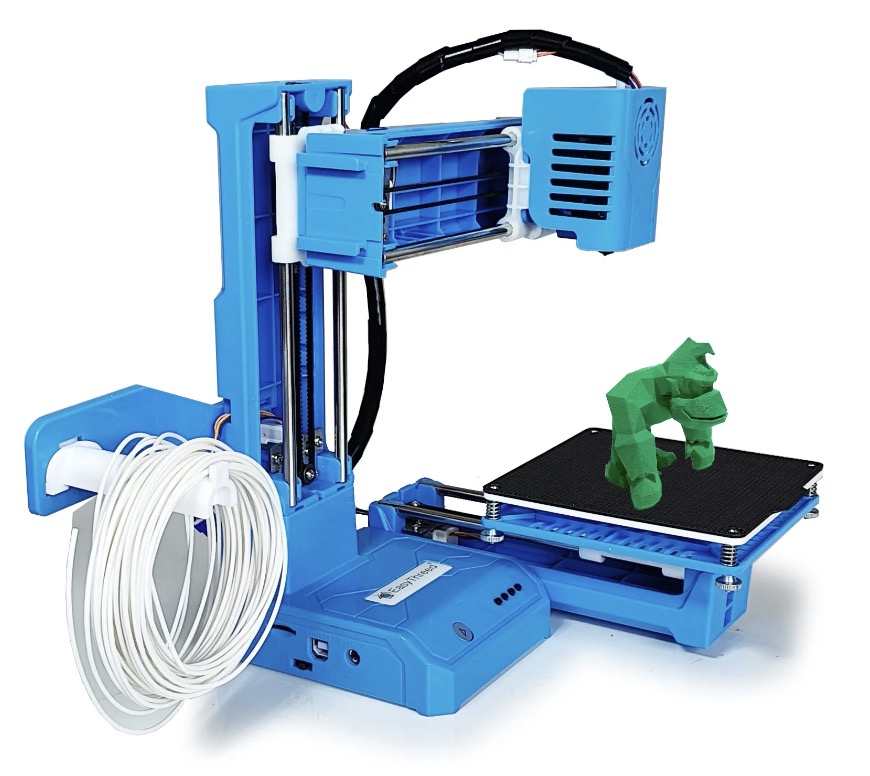

EasyThreed K9 3D Printer for Kids

II. Cost of 3D Printing Toys

The main costs involved in 3D printing toys include:

- Printer Purchase/Lease - Obviously you need access to a 3D printer first. Options range from $100 budget printers to $3000+ industrial machines. Leasing time on a printer can lower costs.

- Filament - PLA and PETG filaments commonly used to print toys cost $20-50 per 1KG spool. More exotic filaments are pricier.

- Electricity - Running your printer's motors, hot end, and heated bed draws power. Estimate 5-10 cents per print hour.

To calculate cost per model, tally the filament used in grams, multiply by material cost per gram, and add electricity costs for total print time. Amortize printer purchase cost over expected yearly prints.

III. Cost of Purchasing Toys

In comparison, picking up a ready-made toy involves:

- Retail Pricing - Mass produced toys cost anywhere from a few dollars for simple items to $100+ for more elaborate toys. Watch for sales.

- Discounts - Retailers offer deals like buying in bulk, coupons, loyalty programs, and seasonal sales to reduce toy costs.

- Used Pricing - Second-hand toys often sell for 50% or more below retail. Yard sales offer deals.

IV. 3D Printing Time Considerations

Time is money, so print duration factors into the value equation:

- Print Speed - Larger, more detailed toy models will take 10-30+ hours to print. Simple toys may finish in 2-3 hours.

- Labor Time - Factoring in print setup, monitoring, finishing, the full labor time may be 2-3X print time.

V. Customization Abilities of 3D Printing Toys

3D printing’s customization strengths give it a cost advantage for:

- Unique Designs - Create totally unique toys not available anywhere else. Copywriting existing toys raises legal issues.

- Personalization - Add custom names, faces, text, and other designs to personalize toys. Not offered for mass produced toys.

- Rapid Prototyping - Quickly test toy designs and make iterative improvements. New toys can be printed in just several hours.

- Rare Items - Produce small batches or one-offs of rare toy designs that are otherwise unattainable.

3D Printed Elephant with Adjustable Joints

VI. Conclusion

Determining if 3D printing toys is cost-effective depends greatly on the specific toy, print time, quantity, quality needs, and value placed on customization. For rare, personalized, or proprietary toy designs, 3D printing has indisputable advantages. In addition, for designers, artists, hobbyists, and small business owners, a desktop 3D printer can deliver unique toy-making abilities at reasonable affordability.

FAQS

1. How much does filament account for in the cost of 3D printing a toy?

Filament is one of the main recurring costs, with typical materials like PLA costing $15-50 per 1KG spool. A medium sized toy may use around 300g or about $5 in filament.

2. What types of toys benefit the most from 3D printing?

3D printing allows fully custom toy designs, personalized toys, rare toys, prototypes, and toys tailored to a child's interests. These specialized cases are where 3D printing shines.

3. What safety precautions should you take with DIY 3D printed toys?

Take care to avoid potential choking hazards from small detached parts. Supervise use, test assemblies, and perform safety checks that mass produced toys undergo.