5 Best Ways for 3D Printer Filament Storage

Aug 03,2023 | 3D4Create

Proper storage is crucial for maintaining the quality and printability of your 3D printer filament. Filament that is not stored correctly can quickly degrade due to moisture absorption, dust contamination, and physical damage.

In this guide, we’ll explore 5 of the best methods for keeping your 3D printing filament stored in optimal condition.

Introduction

3D printer filament must be protected from various environmental factors for best results. Exposure to excess moisture from humidity causes filaments to become brittle, while dust and debris can clog extruder nozzles.

Physical damage like kinks or bends prevents smooth unspooling during printing. Implementing good filament storage habits will save you from headaches and wasted prints down the road.

Store 3D printing filament in sealed airtight containers (photo: Printer Materials)

Determine Whether Your Filament is Wet

Signs of excess moisture in filament include declining print quality, poor layer bonding, and audible popping or crackling from the hot end as the water boils off. While too much humidity damages the filament, it can be recovered by drying. Food dehydrators, low-temperature ovens, or commercial dryers are effective for removing absorbed water. With proper drying, wet filaments can often be restored to usable condition rather than being discarded. Listen for excess moisture and take steps to dry the filament as needed to improve performance.

Dry filament(upper) vs. Wet filament(bottom)

Use Airtight Containers for Filament Storage

Storing filament in airtight containers or bags is one of the simplest and most effective storage methods. Key benefits include:

1. Block Moisture

An airtight seal minimizes air exchange to prevent moisture from being absorbed by hygroscopic filaments like ABS, Nylon, and PETG.

2. Prevent Dust

Keeping filament enclosed limits the accumulation of fine particles that could clog nozzles while printing.

3. Maintain Freshness

Blocking air exposure preserves the material’s mechanical properties and prevents degradation over time.

Store Filament in Cool, Dry Conditions

In addition to airtight storage, maintaining proper environmental conditions is key:

1. Control Temperature

Ideally, store filament in temps between 18-25°C. Higher temperatures accelerate degradation.

2. Use Desiccant Packs

Desiccant packs absorb moisture and keep the interior of storage containers as dry as possible. Recharge packs periodically to maintain effectiveness.

3. Dehumidifier

Running a dehumidifier in your filament storage area prevents moisture in the ambient air from being absorbed. Avoid humid environments, direct sunlight, or extreme temps inside cars or garages. Stable conditions are best.

DIY filament dry box (photo: 3D Druck Vorlagen)

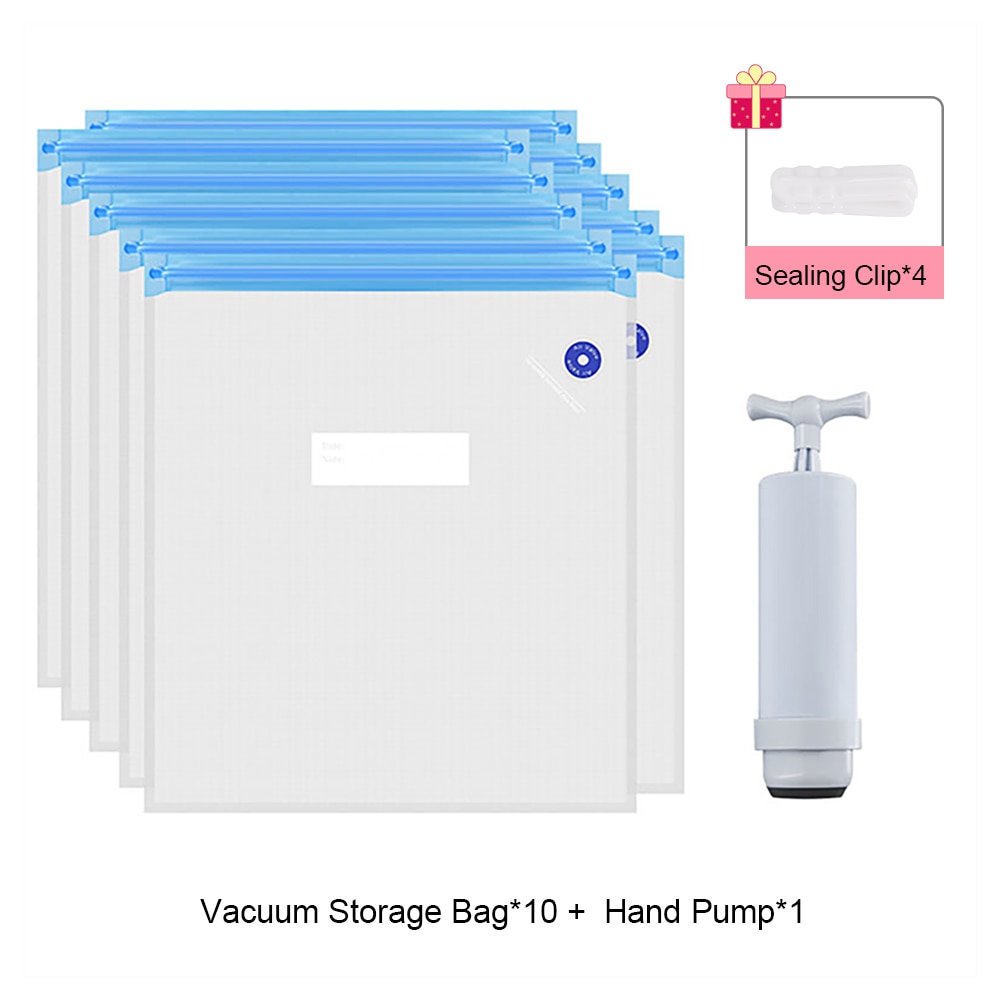

Vacuum Seal Filament Spools for Storage

For maximum protection, vacuum-sealed storage bags are a great option:

1. Remove Air Exposure

Vacuum sealing removes nearly all the air inside, eliminating moisture and oxidation risks.

2. Compact Storage

The bags minimize space since all air is vacuumed out. Easy to organize sealed bags.

3. Easy Dispensing

Special bags allow cutting a corner off for easily dispensing the filament strand while keeping the remainder sealed.

3D Filament Storage Vacuum Bag

Dedicated Filament Drying Systems

Advanced drying systems actively regulate filament storage conditions:

1. Regulate Humidity

Automated systems will maintain an ultra-low interior humidity level between 10-20% RH.

2. Filament Driers

Some systems include integrated filament driers to actively dry filaments before use.

3. Storage with Controls

All critical variables like temp, humidity, and air circulation are monitored and controlled.

SUNLU S2 3D Printing Filament Dryer Box

Proper Spool Positioning of 3D Print Filament

Store spools carefully to avoid physical damage:

1. Upright Orientation

Always stand spools upright. Laying spools on their side can cause flattened sections.

2. Smooth Unwinding

Make sure spools can spin freely without catching on anything for clean unspooling.

3. Prevent Tangles and Snaps

Be gentle when handling to avoid kinks, knots, and breaks which can ruin filament. Proper spool handling reduces jams and inconsistencies while printing. Handle like a delicate asset!

Conclusion

Applying best practices for 3D printer filament storage will maintain your materials in peak printing condition. Use airtight containers, optimal environmental conditions, vacuum sealing, advanced drying systems, and proper spool handling to get the longest life from your filament and avoid preventable print failures. With filament prices continuing to drop, it’s more important than ever to store it properly and maximize value.

FAQS

1. How should you store 3D printing filament?

Filament should be kept in an airtight container or bag with desiccant packs to prevent moisture absorption. Vacuum sealing is also highly effective for long term storage.

2. What damages filament over time?

Exposure to humidity and moisture, dust, direct sunlight, temperature extremes, and physical deformations can all degrade filament quality during storage.

3. How can you restore wet filament?

Filament that has absorbed excess moisture can be dried using methods like a heated dryer, food dehydrator, or low temp oven. This removes absorbed water and restores printability.

See Also

Can 3D Printer Filament Go Bad? - Essential Facts

Unclogging 3D Printer Nozzles: Most Practical Guide